About VACVINA biogas model

The VACVINA biogas model, designed by CRRD, was recognized by MARD who decreed that it could be installed nationwide. CCRD promoted biogas technology through the local network of VACVINA offices. The VACVINA provincial chapter is responsible for continuous monitoring and support at commune level, supervised at district branch level. Supervised by the provincial chapter, district chapters are responsible for monitoring suppliers and managing credit for commune level providers. Biogas service providers take responsibility for the sale, construction and installation of turn-key bio-digesters, training clients and honouring the warranty to households and farmers.

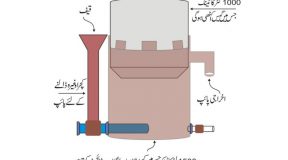

GENERAL ILLUSTRATION OF A VACVINA BIOGAS PLANT

VACVINA biogas System

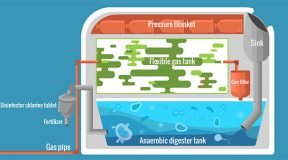

The system consists of a digestion tank (septic tank), nylon reservoir bag and inlet, outlet systems. The digestion tank is a flat-top rectangular underground digestion chamber. The external plastic gas reservoir is made of two to three layers of nylon bag. An ingenious system of inlet siphon allows the new material to be dropped into the surface of the fermenting liquid thus breaking any accumulated scum. The small outlet tank collect liquid waste from the digestion tank through a plastic tube.

VACVINA BIOGAS PLANT The digestion tank:

The main digester is an underground rectangular tank made of bricks and mortar. However, the shape of the tank can be adjusted to the specific configuration and constraints of the family compound while retaining a sufficient volume. One of the great advantages of this model is that the concrete flat top of the digester can provide a clean and dry floor for the pigsty or stable. It also can be build as an integration of the toilet and the septic tank under the stable.

VACVINA BIOGAS PLANT The inlet system:

The hole for the inlet pipe is 30cm diameter and starts from the top of the wall. It can be located on any wall of the digestion tank during the construction time. A siphon connect the mixing tank and the main digestion tank. The standard dimensions of the mixing tank are 0.2 m x 0.4 m with a depth of 0.3 m. This system prevents the formation of a scum layer by regularly wetting and mixing the surface with fresh input.

Watch Introductory Construction Video VACVINA BIOGAS PLANT

The model called "VACVINA biogas", designed by CCRD(RESEARCH & DEVELOPMENT CENTER Farming communities RURAL) (http://ccrd.com.vn). The model has been introduced to Tanzania

Construction Manual: http://www.ease-web.org/wp-content/uploads/2009/08/BIOGAS-MANUAL.pdf

User training: http://www.ease-web.org/wp-content/uploads/2009/08/Annex-2-Training-material_...

Watch Step By Step Detailed Video of VACVINA biogas

Transcript of Video (updating soon)

Biogas is the mixture of gases generated by the bio-degradation organic substances undo anaerobic conditions I wish the main components dismissed and CH4 Biogas not you can bring many benefits to farmers among which

eliminating brawling untreated animal manure and preventing infectious diseases long-term improvement in the financial situation of households by reducing fuel and chemical fertilizer expenses improvement of soil fertility am production of solar deportation by the use of the bio digest hers adjusted eight flint s organic fertilizer reduction of the pollution tossed by chemical fertilizers as peace are totally or partially replaced by more environmentally friendly organic fertilizers reduces the workload of women for few will get the ring including a ports and parents reduction in CO2 emissions and produce the first station pressure by substituting for so feel with biogas

About Biogas Technology in Vietnam

family size affordable biogas technology was introduce in Vietnam in the early nineties since the end various models have been implemented evaluated and modified no model is perfect at present for five or speed up of households participation in Biogas technology is necessary to have a suitable Biogas model which is in accordance with socioeconomic development conditions abroad areas and its most important to be suitable to traditional habits abroad farmers dumping of biogas model is one that is suitable for the condition of rural areas

Instruction on how to construct the improved mapping out Biogas plant

Required construction materials

Construction material required to build standard seven cubic meters bumping up Biogas digester

- a standard solid bricks fourteen hundred pieces

- cement six hundred KG

- course yellow sand 1m3cubic meter

- Gravel one cubic meter

- stone or rubble bricks

- Iron bars construction steel eight millimeters thirty kilogram

Excavating the pit

after selecting and covering the construction site excavation is started the dimensions of the Pete must be larger than those of the digester so as to facilitate the execution of the work the dimensions of the digester can be tailored to specific configurations however to minimize investment and maximize efficiency and ease of operation it is suggested to keep the depth to maximum three meter the with to one point five to two meters and to adjust the left to obtain the total Borland required

important note when there's competition is carried out in an area of high underground water level is necessary to take a ditch around the construction paper throughout construction of the digester base water in come waiting in the ditch can be pumped out to keep this I’ve tried

after completing the excavation of the pit the fallen steps are required to build the base to prepare affairs fifteen centimeter bottom layer a tightly compacted broken bricks or crushed stones dimensioned four by six centimeter poor of five centimeters conquest the nation using one part cement to two part yellow sand three part crushed stone

Important notes

Where the soil is of weak bearing capacity metal rods ten millimeters should be used for the complete later accumulated water must be pumped away regularly use inexpensive plastic sheeting to protect the base from excess water add metal rods rebar in the concrete slab when the soul of has week bearing capacity allow at least twenty-four hours for the concrete to cure....

Video link

http://www.youtube.com/watch?v=ne3RdAmPIbw

Related Articles

- DIY biogas plant

- biogas in urdu

- Biogas Digester Photos

- Biogas Plant Photos from PDBP

- Small scale kitchen waste biogas plant

- Biogas In Pakistan - Pakistan Science Club

-

How Does A Biogas Plant Work?

-

How To Bio Gas Plant Works

-

Biogas Plant Pakistan Science Club

-

gobar Gas plant in pakistan ...

-

Biogas Digester Photos

Discussion about VACVINA biogas Plant http://forum.paksc.org/Thread-Discussion-about-VACVINA-biogas-Plant

Resources

http://ccrd.com.vn

http://www.tatedo.or/news/NEW%20LOW%20COST%20BIOGAS%20TECHNOLOGY%20INTRODUCE

http://www.ease-web.org/wp-content/uploads/2009/08/BIOGAS-MANUAL.pdf

User training: http://www.ease-web.org/wp-content/uploads/2009/08/Annex-2-Training-material_...

http://en.howtopedia.org/wiki/How_to_Build_the_Vacvina_Biogas_Digestor