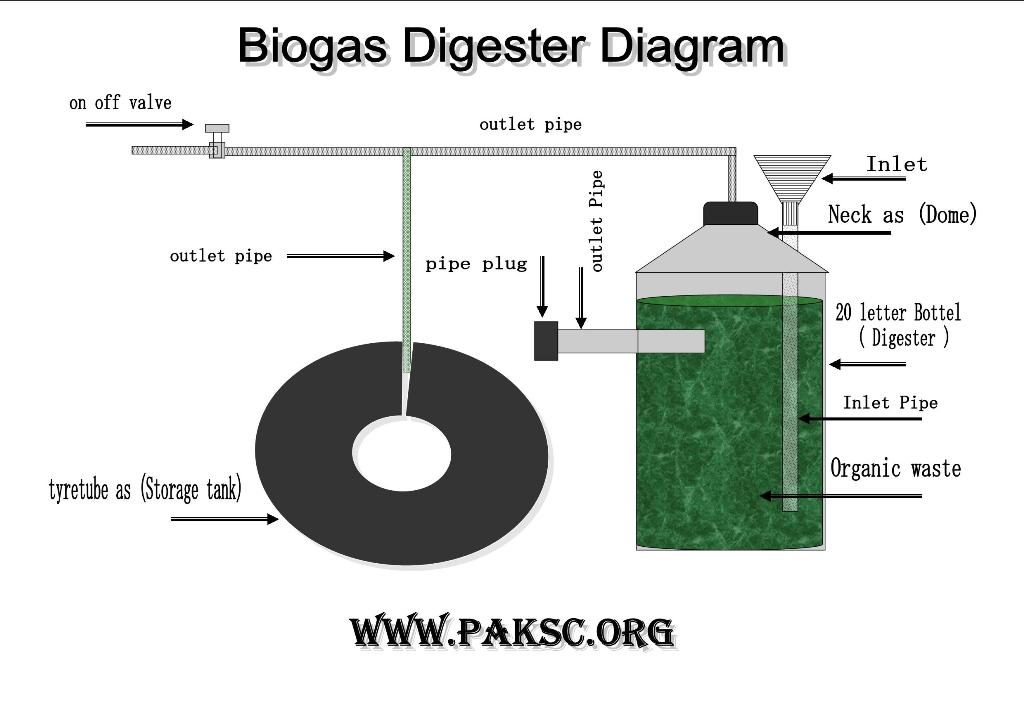

20-litre bottle as Biogas plant and tire tube used as a gas storage tank

The concept of Biogas Plant, Anaerobic Digester

The purpose of this project is to discover ways to produce Biogas with alternate sources by using our local resources. It can help students to basics of Anaerobic digestion and production of gas by different organic kitchen wastage. The basic task is to design, make, test a simple waste digester and gas collection system. One can check various facets of the anaerobic digestion process.

Background Information Biogas Plant

What is biogas?

It is known as a source of renewable energy and it's made mostly of methane (60-70%) and a mixture of CO2 (carbon dioxide), H2S (hydrogen sulfide), NH3 (ammonia), and SO2( sulfur dioxide). This gas is formed when biological matter (usually cow manure), is decomposed in an environment with no oxygen present by bacteria.

It has been popular as a source of energy for over 200 years, To produce biogas, the individual has to first build an anaerobic (no oxygen present) digester, or an enclosed tank (usually made of steel), where specific types of organic wastes are placed for bacteria to decompose them. In the environment, it is produced naturally in deep soils, lake bottoms, and wetlands.

Safety caution!

Biogas is mostly consist of methane, it is highly explosive and dangerous. There should be no flames or electrical items around the digester. Some elements and molecules present in biogas can cause suffocation. The digester should be placed in a well-ventilated area. After handling the digester or any organic matter, that person should ALWAYS wash his/her hand thoroughly with plenty of soap and water.

Carbon dioxide will asphyxiate a person if he/she breathes it. Severe H2S can harm the lungs and other tissues involve in breathing. We will need biomass to make an anaerobic digester. For example, cow manure, grass clipping with soil or any other waste, cow manure serves a starter to produce biogas.

A digester needs certain conditions to work properly. For example, there should be a water-biomass ratio of 1 to 5. The pH of this mixture should always stay around 7, acidic or basic pH level will kill the gas-producing bacteria. A temperature of 0°C to 69°C, higher production is between 29°C and 60°C. There will be high production at temperature equals to 35°C.

The small amount of fresh biomass should be added daily to have enough fresh bacteria to produce large quantities of biogas. After this step, agitates the digester (shake well if it is a small bottle) to mix the biomass with the water. The recommended time for a home-made project is a minimum of 2 weeks.

Note: When using manure from any animal remember: ANTIBIOTICS MUST NOT BE GIVEN TO THE ANIMAL!!

How to Make Biogas Plant

Materials And Equipment

-

- Digester seed material

- Digester feed stock Animal dung, vegetables)

- 20-litre water can

- 1/4" plastic tubing - possible use in the gas collection system

- Medium size Tyre tube for gas storage

- Tub for mixing water feedstock

- PVC Pipe 3/4" 2.5 ft

- T-valve

- Valve

- Super Glue

- Fine Sand

- Soldering Iron

- Black Color Paint

Download Biogas Digester Diagram

Procedure:

Make the biogas digester according to the diagram, if you can not understand so you can watch following video (Note the video is in Urdu language but you can turn on the subtitle.

Few Photos during biogas plant construction in 2012

Important Note:

The biogas plant is a digester and it involves the production of highly combustible methane gas while constructing a prototype, keep in mind the following precautions

- The container must be airtight, as we know that it’s a digester, that digests the biological waste anaerobically (strictly in the absence of air).

- Do not use transparent or translucent containers. If it is transparent, paint it black because it keeps the temperature steady, sunlight encourages the growth of algae which retards biogas production.

- Use standard gas fittings (i.e gas pipes, gas nosels) as it is a highly flammable gas

- Use animal manure per container's dimensions, (i.e. in case of 20 l container 18 or 17 l of a mixture in ratios of 50% dung and 50% water is prescribed)

- For the first time. use animal dung after any other biological waste that may include plants waste; dried dung, dried leaves, paper etc. But keeping in view that must be mixed in a ratio of 50% with water and shaken well.

Watch a video tutorial of this Biogas Plant

FEEDING IN THE DIGESTER

- Leave the outlet open while feeding in the digester so that slurry (the digested mixture of dung and water) comes out of the outlet.

- The first production of biogas bring up slowly, so be patient, it may take as long as one complete week to produce gas.

- Add one litre of fresh feed consisting of biological waste and water in 50% ratio to the digester to keep it in good working condition.

- The cheaper, effective and the safer method to store biogas is old tire tube. (i.e. bicycle tire tube or car tire tube as per the dimension of digester)

PRECAUTIONS

- Avoid the biogas digester from getting in direct contact with sunlight.

- Avoid it from high-temperature variations (Neither too hot, nor too cold )

- It must not go out of 30C – 40C temperature variations.

- Use all safety precautions when testing the biogas, must keep the valve face away while testing the biogas.

- If you do not find any results after one week of feeding in a biogas digester. Check the pipes for dung or water blockage.

- Dung from the animals who are being or were injected antibiotics recently for any reasons is highly harmful.

Video: Science Project DIY Biogas Plant (Anaerobic Digester) Construction

- Mini Biogas Digester Project Photo Gallery 2

- Discussions about Mini Biogas Plant Science Fair Project Help

- Biogas Plant Design

Photos of Biogas plant (Anaerobic Digester) in action

| Biogas plant (Anaerobic Digester) in action |

|

|

| Biogas plant (Anaerobic Digester) in action |

|

| Biogas plant (Anaerobic Digester) in action |

BUILDING UP A PROTOTYPE BIOGAS PLANT

The biogas plant is a digester and it involves the production of highly combustible methane gas while constructing a prototype, following prescriptions must be followed.

- The container that we are using must be airtight, as we know that it’s a digester, that digests the biological waste anaerobically (strictly in the absence of air).

- Transparent or translucent containers are not to be used for this purpose; it must be painted black because it keeps the temperature steady if sunlight passes through the container it shall encourage the growth of algae. That is quite lethal for the production of biogas.

- Keeping in view that its highly inflammable gas, standard gas fittings must be used in this project. (i.e gas pipes, gas nasals)

- Animal manure must be used as per containers dimensions, (i.e. in case of 20 l container 18 or 17 l of the mixture in ratios of 50% dung and 50%water is prescribed)

- For the first time. Animal dung must be used later on any biological waste that may include plants waste; dried dung, dried leaves or even paper can be used. But keeping in view that must be mixed in a ratio of 50% with water and shaken well.

FEEDING IN THE DIGESTER

- While feeding in the digester, the outlet must stay open so that slurry (the digested mixture of dung and water) comes out of the outlet.

- The first production of biogas bring up slowly, so be patient, it may take as long as one complete week to produce gas.

- Daily one litre of fresh properly mixed biological waste and water in 50% ratio shall be fed in the digester to keep the digester in good working condition.

- The cheaper, effective and the safer method to store gas is old tire tube. (i.e. bicycle tire tube or car tire tube as per the dimension of digester)

PRECAUTIONS

- Avoid the biogas digester from getting in direct contact with sunlight.

- Avoid it from high-temperature variations (Neither too hot, nor too cold )

- It must not go out of 30C – 40C temperature variations.

- Use all safety precautions when testing the biogas, must keep the valve face away while testing the biogas.

- If you do not find any results after one week of feeding in a biogas digester. Check the pipes for dung or water blockage.

- Dung from the animals who are being or were injected antibiotics recently for any reasons is highly harmful.

See Also

- DIY biogas plant

- biogas in Urdu

- Bio-gas Plant Photos from PDBP

- Small scale kitchen waste biogas plant

- Biogas In Pakistan - Pakistan Science Club

- How Does A Bio-gas Plant Work?, How To Bio Gas Plant Works

- Biogas Plant Pakistan Science Club | gobar Gas plant in Pakistan

- Digester Photos

- DIY biomethane

- DIY Bioreactor

- Bioreactor experiment

- Biofuel & Biomass Energy Science Fair Projects & Experiments

- digester design

- anaerobic digester system patent

- anaerobic digester definition

- article anaerobic culture

- methane digester companies

Please Feel free to ask any this about this project

Biogas plant construction in Urdu | Biogas Plant ki Tameer

Some common FAQ Biogas Plant:

please visit for the answer https://paksc.org/community/groups/do-science-help

16 Comments

Mini Biogas Digester Project Photo Gallery - Pakistan Science Club

(April 8, 2022 - 10:20 am)[…] More Detail. Here Biogas plant (Anaerobic Digester) Experiment […]

your moma

(March 2, 2022 - 7:13 pm)why? because of you I need to read all of this >:v

But still it’s a good job

shafey

(January 30, 2022 - 9:25 am)excellent job dear

Abdul Rauf

(January 30, 2022 - 9:30 am)Thank you

Ali Nadeem

(January 30, 2022 - 9:21 am)Excellent project

Abdul Rauf

(January 30, 2022 - 9:30 am)Thank you

shafey

(January 30, 2022 - 9:15 am)excellent project

Abdul Rauf

(March 6, 2020 - 6:00 am)some time it contain more CO2 than methane so it can not catch the fire so you have to empty container and wait for next filling.

Umesh Prajapati

(February 18, 2020 - 12:27 pm)Hi Abdul, I used fresh cow dung in my experiment as you answered me on youtube. It was all successful and produces a good quantity of methan. I also tried vegetable peels and kitchen wast mixed with outflow of fermented cow dung. It produces something but this time it is not burning. Can you explain where am I doing mistakes?

abdul rauf

(February 10, 2020 - 2:20 am)Cow dung should be wet and the amount of biogas can be calculate with upside down container

ayeza

(January 18, 2020 - 2:17 pm)Can you help me please. How can you calculate the amount of gas produced in a 20 L bottle? If i will be having 18 L of 1:1 ratio of water and cow dung?

And is the cow dang used wet or dry?

paul

(September 8, 2019 - 3:28 am)please tell me how long does it last when i make the same biogas plant using animal manure and food wastes (pls separate the two)

Abdul Rauf

(November 25, 2018 - 5:22 pm)please do comments if you have any question?

Prince Sheraz

(January 28, 2017 - 5:44 am)please tell me how much gas will produce in 200 litter tank andalso tell me that how much kg/g in one 1 cubic meter thankxxxx

Abdul Rauf

(November 9, 2018 - 1:51 pm)it produce 0.3 to 0.5 meter cube

Abdul Rauf

(March 4, 2015 - 4:31 pm)Old 33 comments

Wednesday, 11 February 2015 22:56 posted by chrissti

what are you changing in the experiment?

Saturday, 20 September 2014 18:47 posted by Muhammad Afzal Khan

Well Done, Please explain the amount of gas we produce with one 10 kg dung and water filling, May we cook 1 month food for a normal family, Best Regards, Muhammad Afzal Khan

Tuesday, 26 August 2014 11:48 posted by ABDUL

@ Marian

Dear Marian

Thanks for comment I will try to answer your questions.

1st

1. Should the input pipe be long until almost reached the bottom of the tank ?

Ans. yes input pipe should be 2 or 3 inch above at the bottom.

2. The mixture has to be supplied via input pipe daily ? Can this be let open ? This INLET pipe will be in contact with the oxygen from air, so it is ok ?

Ans. Yes daily fed is must after feeding you have to close inlet with cap or with other stuff . pipe can be in air there is no effect on gas production

3. The gas output pipe is fine, i got it how it works and where it will be connected.

4. The output pipe for the mixture is quite unclear for me. How it works ?

Ans. output pipe cap only open when you will feeding to digester, outlet pipe use to excrete digester waste.

In my tank, how should we place it ?

Ans. your diagram of digester is fine you can make like diagram.

If it is too low, the mixture will get out.

I Can not understand this question

If is too high, the mixture will get air through it and the produced gas will be mixed with O2 and it will not have the desired effect.

you can also see this link http://paksc.org/pk/biogas-plant-design here is some useful article and videos I hope you will understand

Flag As Spammer

Tuesday, 26 August 2014 11:29 posted by Marian

Hello,

I am writing you from Romania.

I am looking to build a biogas plant at home and i have looked at some designs on the Internet.

Before i start building it, i just wanna get cleared with some questions.

Can you guys help me to build it ?

Mainly, i have some 300-500 liters tanks made of iron. I have made a design but i am not very sure o it.

1. Should the input pipe be long until almost reached the bottom of the tank ?

2. The mixture has to be supplied via input pipe daily ? Can this be let open ? This INLET pipe will be in contact with the oxygen from air, so it is ok ?

3. The gas output pipe is fine, i got it how it works and where it will be connected.

4. The output pipe for the mixture is quite unclear for me. How it works ?

In my tank, how should we place it ?

If it is too low, the mixture will get out.

If is too high, the mixture will get air through it and the produced gas will be mixed with O2 and it will not have the desired effect.

I have seen some designs, where the digester tank is bigger. The tank has the upper side cut and we can fit a smaller cut tank that acts like a gas collector. I don’t really understand how this works. The mixture is fed through the input pipe, and the mixture gets the upper tank up. In this case, the upper tank, being smaller than the one from bottom it will leave some margins where the mixture will be in contact with the air. Is this ok ? Can you explain it a bit ?

How is the outlet pipe working in this case ?

Basically we have the input and output pipe but also we have the area that is in contact with the air. We can feed the mixture through that side that is in contact with the air and when it will overflow it will send the surpuls of mixture out.

Can you explain a bit ?

Looking to hear news from you !

Thank you and best regards From Romania !

Sunday, 20 July 2014 11:08 posted by deepak

very simple and excellent presentation.

Friday, 25 April 2014 13:15 posted by George Kiama

I have really learnt alot about Biogas production from the people of Pakistan.I intend to start my own biogas plant.Here in our country Kenya many people do not know about biogas.I will use the knowledge i have gained to help others.Thank you.

Monday, 21 October 2013 06:51 posted by ABDUL

@Maurice

yes we have made large one for home use you can visit http://www.paksc.org/pk/our-projects/item/747-small-scale-kitchen-waste-biogas-plant.html

and I didn’t found any problems with smells or H2S or NH3. The temprature of the digester remain constant in winter because I used cotton around the digester for insulation.

Flag As Spammer

Monday, 21 October 2013 05:30 posted by abdulrauf

yes “Ian” you can use fruit peel as digester feedstock but it should be blended

Tuesday, 08 January 2013 12:40 posted by Ian

can i use it just using a fruit peels like mango?? please answer

Thursday, 20 December 2012 13:39 posted by Maurice

A great project, well done. Have any of you installed one of these for home use? Any problems with smells or other gas problems H2S or NH3?

How have you kept the temperature stable?

Wednesday, 21 November 2012 18:16 posted by ABDUL

@arslan ali

20 letter of dung and water fill 4 time Tyre tube, 7 to 10 days required to produce biogas

Flag As Spammer

Wednesday, 21 November 2012 18:12 posted by ABDUL

@Siti

the inlet and outlet pipe closed with pipe caps, this caps stops slurry to go back, and gas pressure remain constant.

Thanks

Flag As Spammer

Wednesday, 21 November 2012 17:24 posted by Siti

hello,

how you stick the plastic tubing to the tyre tube?? what tool you used? i don’t know how to make sure the gas didn’t go back to the digester?

im really interested in this experiment, hope you can reply as soon as possible 🙂

Wednesday, 21 November 2012 17:22 posted by Siti

hello,

how you stick the plastic tubing to the tyre tube?? what tool you used? i don’t know how to make sure the gas didn’t go back to the digester?

im really interested in this experiment, hope you can reply as soon as possible 🙂

Sunday, 28 October 2012 07:43 posted by Mark Ng

I am a Mechanical Engineering Undergraduate Student in Renewable Energy from Malaysia

Thank you sharing on how you guys carry out this mini Biogas project

It really makes me amazed that even teenagers nowadays have brilliant mind

Keep up the good work!

Thank you

Thursday, 25 October 2012 19:42 posted by ewache

boy, you too much… this is so great. i love it. keep it up. the world is in need of you. thank you… you videos were not in english so i could hardly pick the words. if i may ask. what was the other attached pipes for/,

Tuesday, 09 October 2012 13:18 posted by Renjan

excellent idea

Monday, 17 September 2012 05:30 posted by arslan ali

hy nice work but i still want to how much gas will produce “quantity of gas?”

also till how many days the methane produced can be used

Wednesday, 15 August 2012 19:42 posted by muni raval

great. thanks a lot for making it easy to understand.

Friday, 01 June 2012 17:51 posted by imran ali

i like this brother

but how much gas it produce

Sunday, 15 April 2012 17:14 posted by Darmore

This is very interesting. I am about to work on it,but i didn’t understand the issue of the old tube.

I would be very grateful if i am fed back.

Tuesday, 03 April 2012 08:01 posted by max clamor

very nice experiment and interesting for all.

Wednesday, 29 February 2012 15:56 posted by Sana Mehmood

Dear Gene thanks you for your attention to safety matters we have idea about the risk of that project , we also mentions it Safety caution in that article.

regards

Sana Mehmood

Friday, 10 February 2012 04:27 posted by gene

methane gas is odorless,colourless how can you assure the safety of people using this kind of gas without asking yourself first what should i do if i have a leaking pipe gas without knowing it because its odourless , colorless and flammable type of gas.your design of simple biogas set up is a good project but not safe for others to try especially for students like your age. although the main focus of your project is using alternative energy you must also consider the safety of others by emphasizing “how can i use this technology with out harming me and others”.whats good with new technology if using it might cause more harm than good.anyway your project is good as for now but dont be discouraged or angry by my comments its just im trying to suggest that you must push forward to make your project not just as a project but a very good one.

Wednesday, 08 February 2012 05:43 posted by hamayon baig

after watching this video i feel that Pakistan is great.

Wednesday, 08 February 2012 00:49 posted by Stefan Hartmann

Why do you have 2 pipes in the digester ?

What is the horizontal pipe for ??

Just to exit the used up slurry ?

Many thanks.

Great project !

Regards, Stefan.

overunity.com

Sunday, 05 February 2012 22:13 posted by MOhammad zada

This is good and great project, but I want to know that above project are just a sample or we can use it for home need and if it is not sample so how much gas (for how long time we can use) this production

Sunday, 05 February 2012 17:36 posted by SANA MAHMOOD

SIR, NICE WORK…

PAF CHAPTER KI VIDEOS UPLOAD KRDN TO BTA DIJYE GA….

GOOD FEED BACK U HAVE..

Saturday, 04 February 2012 13:46 posted by Mohammed Benzaghi

This is very nice… I want to use this as my project work. Please can you give me a detailed video or instruction about how to construct the digester for my project work?

Wednesday, 01 February 2012 16:47 posted by MUBASHSHIR

THIS IS YOUR VERY NICE PROJECT, BECAUSE THIS IS A VERY SIMPLE AND A SAFE METHOD TO PRODUCE GAS. I ALSO WANT TO MAKE MORE FANTASTIC PROJECTS AS SUCH KIND. .

Tuesday, 31 January 2012 07:50 posted by Latif Farooqi

This is an easy & safe way to help reduce the energy crisis in Developing countries, additionally it also stops the cutting of trees, to be used a fuel. Well done for such helpful information.

Friday, 27 January 2012 14:23 posted by Suleman Shafqat

Great work buddies

This is how we can make it up

Slowly slowly stair by stair we can make up our country high

Be motivated guys

Youngsters ROCK 😉

Thursday, 26 January 2012 17:45 posted by Demahom seena

Dears,

We are an International students, well we went through your project, we really appreciate about it, although we need your explanation regarding these raw materials. Please give as an explanation how to mix raw materials and how it should be. can we add dried wastage from animals as well as plants.

We need your further assistance, We are look forward to hearing from you.

Students.